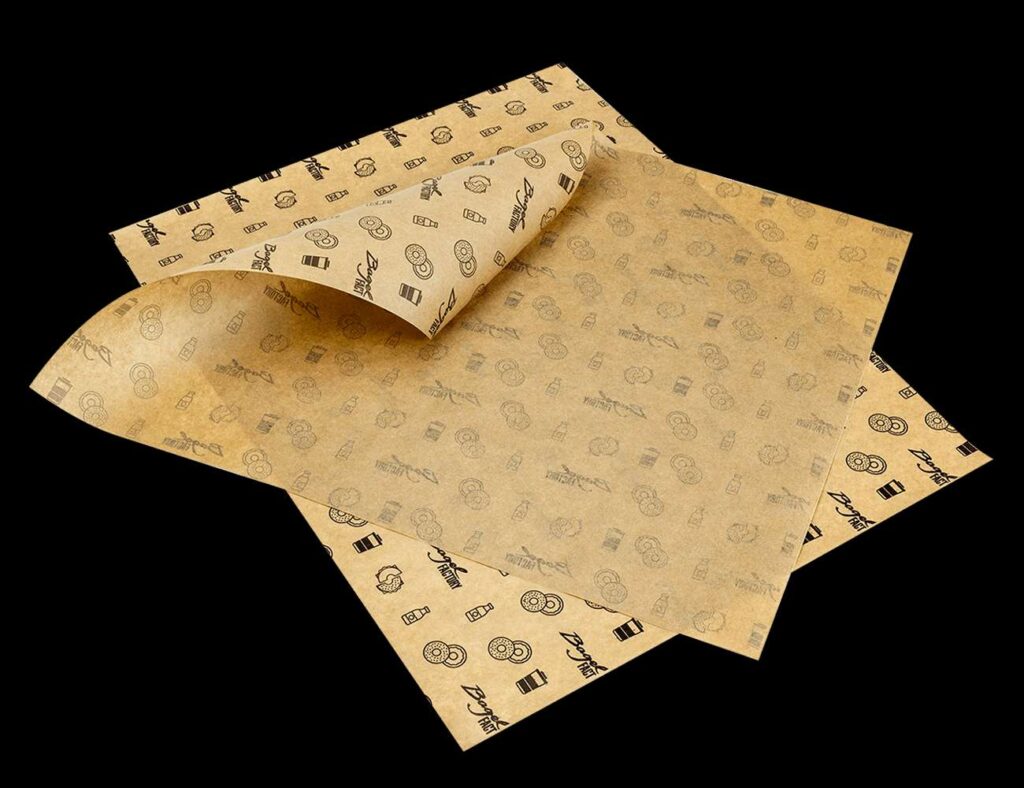

Custom paper orders are not only a purchase but an investment in branding and protecting the product. The businesses have to check out all the details before making an order to prevent errors that may influence the quality, cost and customer perception. In terms of print quality, colour, to the choice of material, in-depth pre-order inspection is what will guarantee a smooth production process.

Considering these factors helps in minimizing wastage, eliminating time wastage and ensuring satisfaction with the end product. The need to evaluate carefully is part of ensuring that the packaging meets the desired effect of impressing and protecting it is also part of the professional standards.

Quality Checking of Materials

The initial stage of Custom Paper evaluation is the knowledge of the specifications of the material. Durability and presentation are important factors that require thickness, weight and finish. As an example, premium paper will make the packaging withstand handling, shipping, and storing without tearing or wrinkling. The selection of the appropriate type of paper, matte, gloss or textured, has a bearing on functionality and beauty. The verification of the material also guarantees that custom prints are not stuck, colours remain vivid, and lines are sharp. It is better not to ignore this step, as it may break the protection of products and aesthetic appearance, compromising the brand’s integrity.

Precise Measures are Important

In placing orders for custom paper rolls, size and dimensions are very important. Directly related to usability and cost are length, width, and thickness. Rolls which are too big may result in waste, and the size of the sheets may not be good enough to cover the products completely. Measurements must be in accordance with the product dimensions and use. Folding, cutting and packaging efficiency should also be taken into account as margin allowances in businesses. Pre-checking this information will save the errors that cost a lot, will make everything fit correctly, and will keep the final product in a professional appearance, both in wholesale and retail.

Colour and Print Consistency

Wrapping paper that has been custom printed requires consistency in printing. Colour schemes must be in line with the brand palette, and designs must be the same in batches. Sample prints may be used to prove by using a sample print rather than having a blurry pattern. Fine artwork will make the logos, graphics and text clear and sharp. Companies ought to check colour schemes, types of ink and coating to ensure that the final product is what is expected. Missing this step may result in inappropriate printed results, colour loss; this may decrease the customer attraction and brand reputation.

Design Proofing Importance

Provide custom-printed papers before commitment. These are layout, font size, spacing and graphics positioning. Proofing enables the business to identify mistakes or inconsistencies that may devastate the finished product. Digital mock-ups and sample prints allow a client to have a physical preview and make the client realize how the sheets, rolls or bags would look in practice. Early planning helps to save time as well as money, whereby branding aspects are well represented. This is important, especially when doing large orders or complicated designs, to ensure consistency and professionalism.

Quantity and Order Size

Checking the volume of orders is a necessity in the purchase of custom paper in bulk. The number of sheets will be insufficient to cause shortages, whereas excess will raise storage expenses. This is because when the correct needs are calculated according to product line, seasonal demand and marketing campaigns, efficiency is achieved. Bulk purchasing may be more effective, yet it should be adequate for their production schedules. With good planning, there will be no over-stocking or under-stocking, there will be a balance between money invested and the operation, and the packaging materials will be delivered on time.

Supplier Reliability Check

Choosing a reputable supplier is important in order to order custom wrapping papers. Timely delivery, quality production, and responsiveness fall under the reliability. Vertical research on reviews of the supplier, certification, and previous experiences of clients can be used to evaluate regularity and professionalism. A reliable supplier would make sure that the production problems, design clarification and emergency changes are managed effectively. By putting money in a reputable supplier, risks arising due to slowing down or inferior materials are reduced, protecting the brand and working processes.

Final and Operational Characteristics

Special characteristics may be added to custom paper, such as perforations, laminations or coatings. Cross-examining these specifics to make custom paper bag orders is to make sure that functionality matches the purpose. A case in point is that laminated surfaces might be used to enhance durability and resistance to moisture, and perforated lines can be used to enhance usability for wrapping or tearing. Other functional checks are fold strength, adhesive quality, as well as print alignment. All these aspects properly used will contribute to a well-done and professional presentation of the product.

Cost and Budget Alignment

Before ordering Custom printed boxes, ensure that the order fits within the budget. Paper type, complexity of printing, finishing and quantity of paper are some of the factors that differ in prices. Surprises can be avoided by making comparisons among multiple suppliers and determining their overall costs, shipping, and possible revisions. Businesses ought to consider between quality and cost and therefore make packaging investment as a reflection of brand positioning without damaging the material integrity. Finding a balance between cost expectations and design and functionality will guarantee an easy process of placing an order and getting maximum returns on investment of the materials used in packaging.

Conclusion

Paper orders that are tailor-made need to be followed up with a keen eye on the quality of materials, their sizes, colour precision and reliability of the supplier to achieve a smooth process. Since the designs are proofed to the finishing features, each detail serves the brand image or product protection. Proper quantity to be used, functionality additions and cost matching will ensure that the packaging is professional and high-performance.

These checks prior to an order are good to minimize the number of mistakes, save money and enhance customer satisfaction. Good preparation turns plain paper into a powerful, branded packaging tool that helps to raise the product attraction, as well as business objectives.